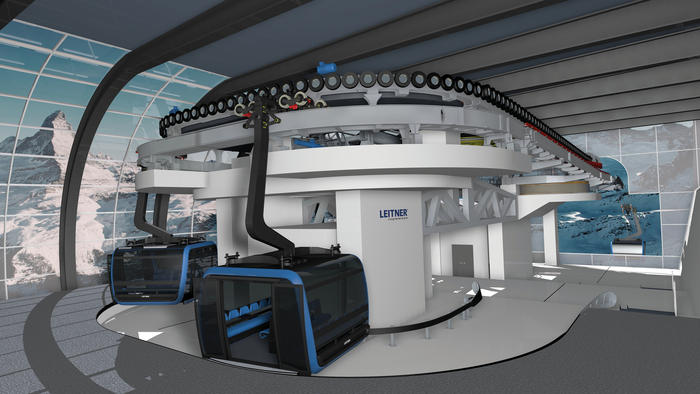

Zermatt’s latest attraction, the “Matterhorn glacier ride”, is set to open at the end of September. The world’s highest 3S cableway, combining the ultimate in design sophistication with maximum comfort, will serve Europe’s highest cableway station. The new 3S cable car ride built by LEITNER ropeways will enable visitors to reach the Klein Matterhorn, a popular destination for excursions, 365 days a year. The making of the “Matterhorn glacier ride” is a story as extraordinary as the ride itself. A total of 38 companies from Switzerland and Italy have been involved in Zermatt Bergbahnen AG’s largest-ever construction project. With the project due to be completed in an incredible 600 working days, they are turning the vision of the “Matterhorn glacier ride” into reality. Zermatt Bergbahnen AG and LEITNER ropeways worked together with Swarovski to produce a very special premium product: a state-of-the-art ropeway technology in Pininfarina design meets premium crystal finishing, and provides an as-yet unrivalled level of finishing and design.

Europe’s highest construction site

145 people from 38 different companies have been involved in the biggest construction project in the history of Zermatt Bergbahnen AG. From September 2018, the 3S (three-cable system) cableway will transport up to 2000 passengers an hour to Matterhorn glacier paradise (Klein Matterhorn) – 365 days a year.

The Klein Matterhorn usually has daytime temperatures as low as minus 30 degrees, wind speeds reaching 240 km/h, heavy snow and dense fog.

Since 2016, construction workers in expedition gear have been working on the new Matterhorn glacier ride at almost 4000 metres above sea level and on precariously steep terrain. Because of the lack of oxygen at high altitude the individuals toiling on Europe’s highest building site can only perform at around 60 to 80 percent of their normal physical capacity. The altitude is not only tough on the workers – the materials too are pushed to the limit. Concreting work can only take place at temperatures of 5°C or more, so the concrete is mixed using warm water at the intermediary depot at Lake Cime Bianche on the Italian side of the border and must not be allowed to cool below 8°C during its journey on the transport lift. The construction machinery also had to undergo technical modifications to cope with the extremes of pressure and temperature. At an altitude of almost 4000 metres the air pressure, as well as the amount of oxygen contained, falls to 60% of that at sea level.

Rock stabilization – protection from falling scree

Before a start could be made on the building work, the site on Klein Matterhorn first had to be made safe from rockfalls. Highly specialized workers from Gasser Felstechnik AG manually put protective netting in place. While abseiling over the rock face from the ridge above, they first used picks and crowbars to clear loose surface rocks from an area of 3000 m2. The high-alpine specialists then pinned hexagonal-weave protective netting over the rock surface, requiring the use of ten tonnes of steel. Four protective nets over the building site and future mountain station protected four more areas of 200 m2 from falling rocks and avalanches.

Excavation – room for the new mountain station

Having ensured the site was safe and once several tonnes of snow had been removed, a crane was erected for use during the rest of the construction work. It was secured to a 3.5-metre-square base with 16 eight-metre anchors. The main challenge now was how to deploy the drilling machines effectively where there was no level ground. “To overcome the problem, we detonated some small charges and used an excavator with a pick hammer attachment to create two temporary access routes from the opening tunnel to the highest point of the construction pit. That way we could get the drill rigs into place and start excavating from above,” explains Thomas Aschwanden, project manager and deputy managing director of Gasser Felstechnik AG. Because of the challenging topography, around one-third of the excavation work was completed not by the two drilling machines but by workers suspended from ropes and using hand drills. The holes, two to three metres in length, were then filled with explosives. Thirty holes were drilled into the rock face each day in this way and an average of 100 m3 of rock removed. Five tonnes of explosives were needed to excavate a total of 10,000 m3 of rock over a period of 90 days. After the excavation work, concrete was poured in an area of 31 by 8.5 metres to form the foundations for the building.

High-alpine material transport

Initially, the construction site on Klein Matterhorn could only be supplied by helicopter, but in the summer of 2016 a materials cableway was built specially for the Matterhorn glacier ride project between the bases at Lake Cime Bianche in Italy and Matterhorn glacier paradise. The 4015-metre materials cableway built by Moosmair GmbH is capable of transporting loads of up to 8 tonnes. When it was built, special attention had to be paid to the cement mix for the anchors, as it had to be usable in conditions of permafrost and could not be allowed to cool during transport. From summer 2016 onwards, most of the construction materials were transported to the high-alpine mountain station on the materials cableway, via a 650 m2 intermediate depot at Lake Cime Bianche in Italy.

Three towers and two station-based supports

There are three towers along the route of the Matterhorn glacier ride and two supporting structures, one at the entrance to each station. These are the five structures that carry the support cables. The supports at the stations also ensure that the cabins enter at the correct angle, as well as supporting the station itself. For both stations together, a total of 1550 m3 of concrete was used, such is the scale of the 3S cableway project – these are vast quantities, which would normally be enough for several cableway installations. 440 m3 of concrete went into the foundations of tower 1 alone (altitude: 2941 metres). All the materials for the towers were transported to the site via Testa Grigia (I/CH) using a snow mobile hitched to trailers. A caterpillar crane from Clausen Transporte was deployed for the assembly work. At tower 2 (3059 metres) the loose ground meant that extensive excavation work was required with massive amounts of earth-moving and a total of 141.5 tonnes of steel reinforcing mesh to anchor the tower securely. The feet of the tower plunge as far as 35 metres into the ground, with only three metres being visible at the top. Work at tower 3 (3771 metres) also posed serious challenges, this time because of the exposed nature of the site. A walking excavator brought in across the glacier had to take away ice before the excavation work on the rock could begin. Once the four foundations had been built, a second crane, 52 metres high, was erected to assemble the tower itself.

High-wire act for cable transportation

The total of five cables for the new 3S cableway set off from the FATZER plant in Romanshorn to cross Switzerland as an abnormal load en route to Cervinia in Italy, where the really challenging stage of the proceedings was to begin. At 80 tonnes each, the five cable reels were too heavy to be transported by a single truck from Cervinia to Lake Cime Bianche (at 2812 metres), so the individual cables first had to be transferred to two smaller reels and loaded onto two connected trucks before being re-spooled onto the original reel at their destination. They arrived in convoy at their destination and were then spooled back onto their original bobbins.

From Lake Cime Bianche the cables were attached to a preliminary cable and winched by means of a temporary cable bridge across Furggsattel (altitude: 3365 metres) and on to Trockener Steg (2939 metres). The much lighter preliminary cable was transported by helicopter to Furggsattel from the Italian side of the border and from there it was possible to span it to Lake Cime Bianche via the cable bridge with the aid of an auxiliary winch mechanism. On the Swiss side, it was possible to install the preliminary cable over the Furggsattel chairlift pylons, partly using the helicopter and partly with the help of a snow mobile. Once the preliminary cable had been spanned, the next step was to attach first the hauling cable and then each of the support cables and send them on their way. All in all the cables covered a distance of over 13,000 metres from their arrival in Cervinia and an elevation change of almost 1300 metres.

Stations assembled from tens of thousands of individual parts

Construction of the world’s highest 3S cableway includes building two new stations from scratch: the valley station is being built to the west of the Matterhorn Express mountain station, at an altitude of 2923 metres, and the mountain station is on the western side of Matterhorn glacier paradise at 3883 metres. No two stations are alike – they are all individually designed to blend in with their natural environment and there are different factors at play in each location.

The first phase involved the manufacture of the individual components at the Leitner factory in Sterzing (in ltaly). These are then pre-assembled at the plant. “Counting every last nut and bolt there are definitely tens of thousands of individual parts,” says Jan Sorg, project engineer at Leitner ropeways. From manufacturing the individual parts to final assembly takes around 6 to 10 months. Before delivery to the construction sites all the parts have to be prepared for transportation. On the Italian side of the border, they are moved from Sterzing to Cervinia, then on to Testa Grigia via the materials cableway, before finally being loaded onto sleds which are towed by piste machines across the glacier to Trockener Steg.

Air Zermatt – precision work without parallel

To date, Air Zermatt has flown several thousand circuits to help build the 3S cableway: transport flights in support of the rock stabilization work on the western side of the Klein Matterhorn, flights for the installation of the building site on the Italian side and flights to help bring materials for assembling cranes at the new mountain station. The wind, the rapidly changing alpine weather conditions, and the fog are all problems the construction workers have to contend with, as do the pilots.

Another difficulty is caused by the steepness of the terrain, which means that the pilots have to be able to fly loads suspended from a cable which is at least 60-metres in length with precision accuracy to the construction site. It’s an amazing balancing act, and one made even more difficult as operating at an altitude of almost 4000 metres stretches the helicopters to their performance limits because of the low air density.

“Working on the 3S construction site on the Klein Matterhorn is one of the most challenging operations we have ever carried out with our helicopters,” confirms Gerold Biner, CEO of Air Zermatt.

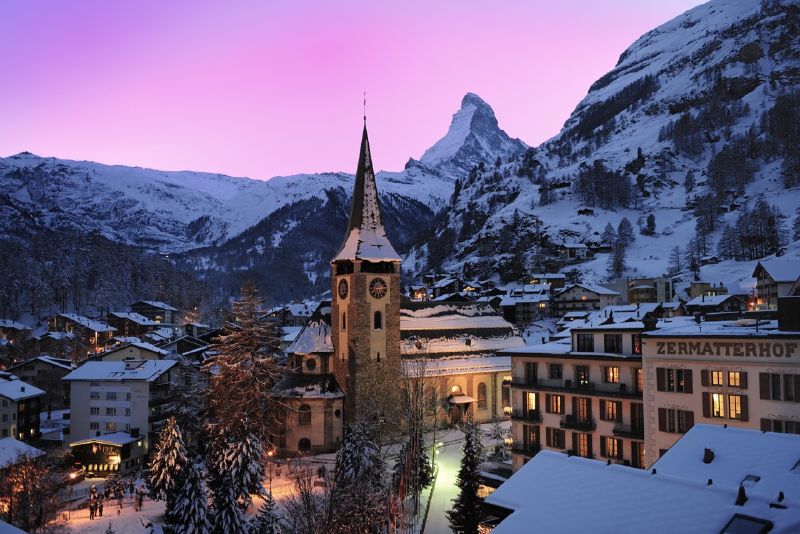

Zermatt has been affected this past season by massive snowstorms- you can see the story here. Or you can see our recent post of trekking with the family in Cervinia. And the Must-READ guide to Zermatt is coming soon. Check here in the near future. If you want The-Ski-Guru Travel to help you planning your ski holiday, please contact us at info@the-ski-guru.com or fill up the form here.

To keep on reading Ski News at your Fingertips, keep on visiting The-Ski-Guru, subscribe to our newsletter and follow us on Social media through our hashtags #skinewsatyourfingertips and #theskiguru.

Featured Image: The new Matterhorn Glacier Ride is opening end of September to take you to the Petit Cervin/Klein Matterhorn. Project by Leitner Ropeways.